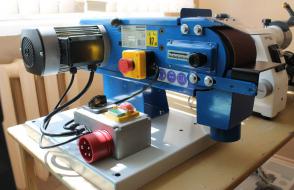

The auditorium 3-13 of building 5 of the Faculty of Physics and Information Technology of our university, was repaired. There were installed laser and milling equipment with numerical control (CNC), 3D printers, as well as auxiliary equipment without CNC. This will allow the students of our university to study the basics of creating control programs for working on CNC equipment, design and manufacture samples of metamaterials, antenna elements and other elements with high accuracy within the course of coursework and diploma design, research work.

Prototypes of metamaterials, metasurfaces and other samples made in this way are planned to be examined in an anechoic chamber of the University in order to study their electrodynamic characteristics. All this expands the opportunities to comprehensively investigate new electrodynamic materials, starting from the stage of computer modeling and ending with the manufacture of working samples with their subsequent study in an anechoic chamber for students, undergraduates and postgraduates of our university. Thus, we can talk about the opening of a workshop for modeling, prototyping and manufacturing of metamaterial samples within the walls of our university. The head of the workshop - Aleksey Balmakov (Ph.D., Ph.D., Associate Professor of the Department of Optics) in 2020 was trained at the Center for Engineering Education, Labor Protection and Industrial Safety of the educational institution "Francisk Skorina Gomel State University". Besides that he has practice at JSC "Stankogomel".

Due to the increasing interest in robotics and programming of electronic devices among youth, the new technology will also be demanded for creating educational equipment for more effective implementation of the educational process within the walls of our university, says Alexey. It should be noted that equipment for laser cutting materials is already widely used in the manufacture of protective shields for medical personnel working in a difficult epidemiological environment.